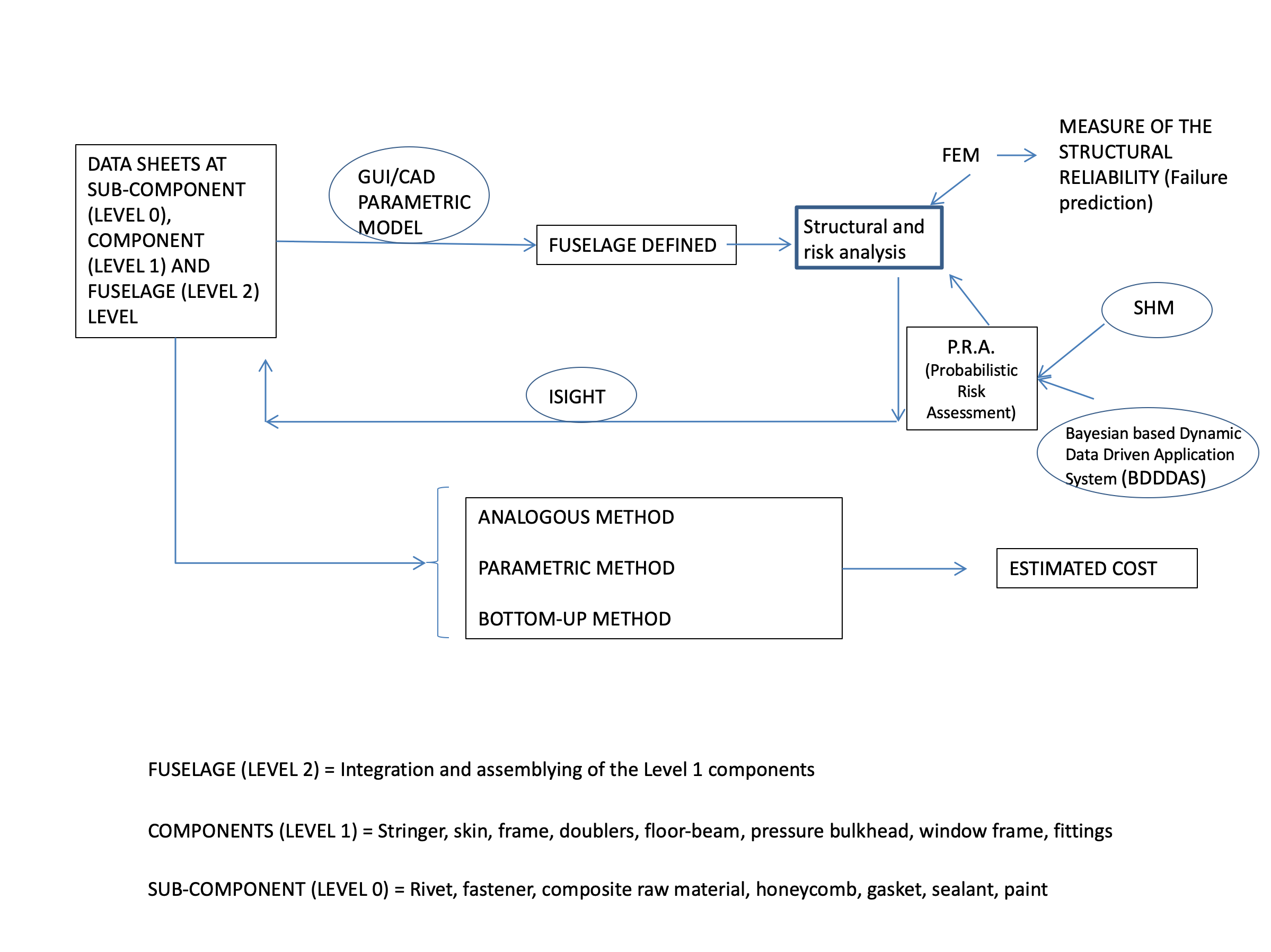

The objective of the call is to develop a multidisciplinary optimization open source software with an included cost model for composite fuselage design, manufacturing, repair and maintenance. The cost model shall include the economic benefit or otherwise of on-board structural health monitoring technologies (SHM) such as Piezoelectric transducers and Fibre optic sensors. The motivation for cost estimation and cost modelling emanates from the desire to economise the future manufacturing costs before or during the product design phase as well as minimizing the costs of maintenance through SHM technologies.

The SHERLOC-Cost-Optimisation open source software (outcome of this call) shall allow for cost estimation and economic comparison of different manufacturing route (e.g. hand layup, automatic tape layup, automatic fibre placement, resign transfer moulding, injection moulding, thermoplastic forming, etc.). The models can be primarily based on detailed cost model estimation method, however, parametric models, mathematically derived are also to be integrated into the software.

SHERLOC-Cost-Optimisation software shall provide a flexible and transparent cost estimation process with appropriate statistical confidence values. The software shall provide platform to adopting different cost estimation strategies generally adopted within the aeronautics industry, namely:

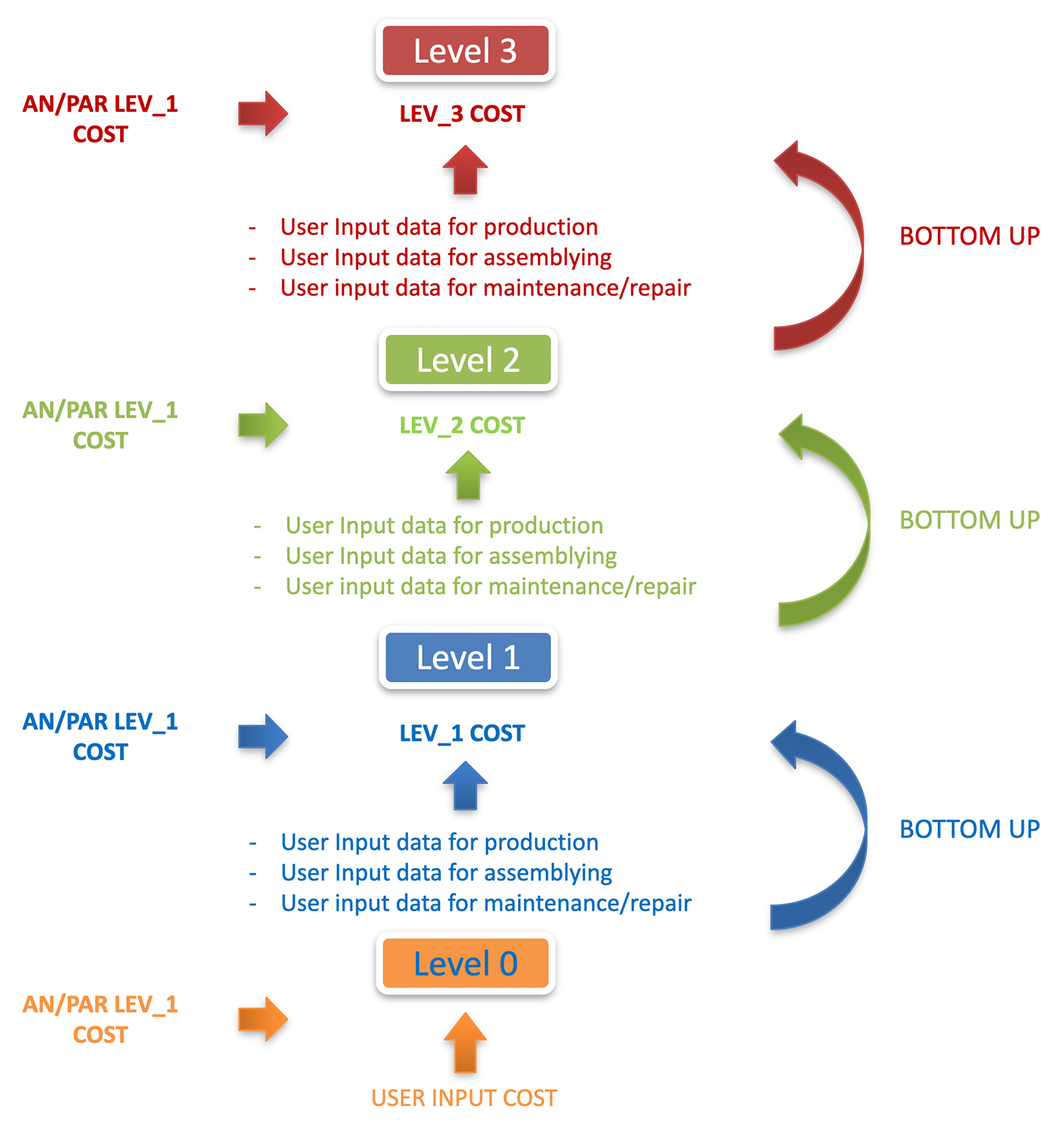

The development of generic cost estimation model utilizing information is of importance as different sub-components have different elements with specific costs attributed to each part. For example, the generic element’s cost attributes may include geometry, material, process and production planning as depicted in Figure 1. The method follows the bottoms up cost estimation approach.

The software shall include technical cost models that accurately reflect the real production environment to correctly evaluate the business case behind new product development. The cost drivers shall include multi-factor sensitivity analysis to understand the trade-off between different process parameters.

The above cost estimation software shall provide a seamless link to the maintenance and direct operating cost modules also to be developed as part of the call as well as industrial commercially available multidisciplinary optimisation and FE software described below.